by Eric Gilliam

Each piece in the MIT series can stand alone for the most part, but I’ve written them in such a way that they build off each other. So, I’d recommend reading Parts 1 and 2 before this piece for optimal pleasure.

As was true of the last two pieces, the majority of the MIT-related information in this piece comes from Philip Alexander’s fantastic work of history called A Widening Sphere: Evolving Cultures at MIT.

The first piece in the MIT series covered the early decades of MIT and its hands-on approach to educating engineers who would disproportionately end up in leading roles as builders in America’s era of peak growth. The second piece of the MIT series detailed early MIT’s radically applied approach to facilitating research that served industry, going as far as to fund certain departments almost entirely through industry contracts. In this piece, the last in the early MIT series (for now at least), I’ll explain the rationale behind MIT’s shift towards more pure research by its faculty and its increased emphasis on the broad scientific training of its students — at the expense of hands-on technical training.

To be clear, MIT is still a very applied research university that serves industry more so than competitors like Harvard. But it is clearly far more similar to Harvard now than it was 100 years ago. The differences in its education are the starkest. A large percentage of MIT graduates 100 years ago would go off and work in mining, power distribution, sewage and sanitation, infrastructure building, or construction. Even those with more scientific degrees like chemistry or chemical engineering would funnel into jobs such as chemical analysis for a paper manufacturer.

The changes in the Institute’s policies towards research were substantial, but far less extreme than the changes in education. In the early 1900s, MIT research staff like Vannevar Bush would often spend a majority of their research time working on projects in partnership with industrial firms. This was not seen as a sideshow to the actual job of being an MIT faculty member. The Institute saw this as an opportunity for the faculty to deploy their expert-level toolkits on the vexing problems of modern industry. Just as importantly, this was the best way for the professors to stay current on ever-changing industrial best practices which they would then pass on to their students. Professors being able to contribute to top-notch industrial research and educate the best engineers in the country in a hands-on, practical fashion was very strongly emphasized in the hiring and promotion of professors. Just being highly cited wouldn’t get you very far on Tech’s campus.

The major shift from this older version of MIT to modern MIT, MIT 2.0, largely began under pre-World War II President Karl Compton. At the time, many on the MIT Corporation and some of the Institute’s most distinguished alumni believed that the needs of industry were evolving. As MIT had been accustomed to doing, they thought the Institute should adapt and train their students for the new future of industrial innovation that was clearly taking shape.

Before I continue, I’d like to make two things clear. The first is that I completely understand the trends that Compton and people like him at the Institute saw that precipitated these changes. The second is that, while the Institute is different now, it’s hard to call what they did a mistake because I — and many others — would still classify MIT as the best at what it currently does. If you’re the best at the new thing, it’s hard to say a mistake was made. But, as I pointed out in the first two pieces, I do believe that it would be better for American progress if some organization, whether it is MIT or anyone else, implemented additional educational and research programs analogous to those of early MIT.

With all of that out of the way, let’s dive into what happened.

What the MIT Corporation wanted

Around 1930, the MIT Corporation (MIT’s Board) was looking for a new president. This time around, unlike previous presidential searches, the search parameters were quite specific. They wanted the Institute to hire a research physicist. The man whose name quickly rose to the top of the list, Head of the Princeton Physics Department Karl Compton, found the Institute’s interest in him strange.

Compton was quite at home in the then-Eden of professorial comfort that was Princeton, New Jersey. He was at home doing the lab work of an experimental physicist and was known to be theoretically driven. His major academic contributions included: inventing an experimental device called the Compton electrometer with his brother Arthur, pioneering work in electrical plasmas, as well as other work related to electron collisions. But, beyond his consulting arrangement with GE, he had not done much industrial-related work beyond his temporary assignments during World War I.

Still, to the MIT Corporation, he was perfect. Not only was he loved and accepted by the pure physics community, but he’d proven himself to be extremely useful in his consulting role with GE. Gerard Swope, then GE President and MIT Corporation member, was Compton’s biggest advocate on the Corporation. Even though Compton was told that he could make MIT’s physics budget as large as he wanted, he still found this offer surprising and a bit of an odd fit. What could he have to offer in the education of students who would go on to build infrastructure or work with heavy machinery?

So, Swope sent Compton to talk with Frank Jewett, the founding director of Bell Labs and MIT Corporation member. In just the same way that a VC develops a thesis of how some industry will evolve in the coming decades and invests accordingly, the Corporation had a thesis about what the future of Industrial innovation looked like and was hiring its next president accordingly. The seemingly inevitable expansion of corporate R&D labs across sectors weighed heavily on their thinking. Philip Alexander writes:

Jewett talked, Compton listened. The Institute, he said, had become stuck in neutral or reverse and needed a jump-start. Its vision —outmoded, if not exactly irrelevant — was not meeting industry needs. MIT’s founder, William Barton Rogers, had conceived and built a place that would lead in science as well as in its practical applications.

But MIT had fallen behind in the former and its approach to the latter bordered on obsolete. For decades, industry had relied on MIT to supply personnel trained in certain techniques, lab methods, shop practices, and other routine functions. In turn, MIT “took on a strong slant of immediate practicality.” But Jewett’s firm (AT&T), Swope’s (GE), and others had evolved with such precise, refined, often proprietary technical demands that they quickly began training their own staffs.

As this trend grew, MIT’s value as a supplier of technical expertise declined. What industry needed from MIT was not so much practical skills as graduates broadly educated in science, mathematics, and basic engineering principles—personnel with minds open to “the anticipation of technological change…some contact with the spirit and methods of research, and preferably some experience in it, so that [they] would be prepared to grasp new technological opportunities and either to participate in their development or at least to understand something of the conditions required for such development.”

This pool, with its more flexible, creative mindset, would help industry take advantage of new opportunities opened up by advances in science. Jewett explained that the opportunity to break with the traditional style of engineering education, and to reinforce the pure sciences, could be realized only under leadership that would move aggressively to build a new type of faculty.

There had been some tinkering around the edges under Samuel Stratton, but nothing like the transformation that Jewett was hinting at. Engineering departments, he said, must have more research faculty, whether trained as engineers or as scientists. In his mind the type of leader most likely to make this happen was a research physicist — not an engineer, or a chemist, or a biologist, but a physicist, someone like Compton, whose background and experience lay at the juncture between academic science and technological know-how.

Jewett laid out a vision that Swope had merely hinted at. This was not the MIT that Compton had heard so much about, productive yet satisfied with its traditional mission. He had dismissed the challenge because it felt like giving up a career for something opposite. But the transition was as natural as one could find — ”an opportunity,” Compton realized, “to draw on this background of experience and my scientific contacts in order to enlarge the scope of their value and influence in the educational and research fields generally.”

He understood the part that MIT had played in American science and technology. In just short of seven decades, it had grown from a small experimental school into America’s foremost institute for technological education. The first collegiate program in architecture had started there, along with the earliest formal coursework in architectural engineering. The first programs in aeronautical engineering, chemical engineering, food technology, industrial biology, naval architecture, and marine engineering — these were MIT innovations. Jewett, however, talked to Compton not about legacies, traditions, or achievements, but about where MIT stood currently, poised at a crossroads, ripe for change in a world where science and technology were moving in unprecedented directions. — A Widening Sphere

This thesis was the North Star that Compton would use to steer the Institute towards a more modern path.

With the benefit of hindsight, we now know that many areas of modern industrial innovation look far more like golden-era corporate R&D labs than others. In the sectors where the Corporation’s vision was right, MIT is, today, elite and extremely useful to industry. In the areas where golden-era corporate R&D lab-style research is less pervasive, it seems like MIT has taken a noticeable step back in the impact it has on those industries.

At the time, though, using this thesis as a North Star was probably a pretty good decision.

The new face of industry R&D

The Corporation’s vision of where industry was going was very prescient. Their predictions proved quite accurate, at least for the next three to five decades — you really can’t expect people to make predictions over a longer time horizon than that. In this mid-1900s period, corporate R&D labs grew in number, scope, and size for all types of large industrial firms. Bell Labs, GE, and DuPont are just a few very famous examples of this larger trend. (Representatives from all of those companies sat on the MIT Corporation.)

The number of scientists employed in corporate labs in the chemical industry, for example, tripled between 1921 and 1933, from 1,102 to 3,225. It then exploded again, growing to 14,066 by the end of World War II.1 And this general growth in applied R&D investments continued in the post-war years, peaking in the 1960s.

Describing some of the highlights of the corporate R&D ecosystem, Robert Gordon writes:

Much of the early development of the automobile culminating in the powerful Chevrolets and Buicks of 1940-41 was achieved at the GM corporate research labs. Similarly, much of the development of the electronic computer was carried out in the corporate laboratories of IBM, Bell Labs, and other large firms. The transistor, the fundamental building block of modern electronics and digital innovation, was invented by a team led by William Shockley at Bell Labs in late 1947. The corporate R&D division of IBM pioneered most of the advances of the mainframe computer era from 1950 to 1980. Improvements in consumer electric appliances occurred at large firms such as General Electric, General Motors and Whirlpool, while RCA led the early development of television.

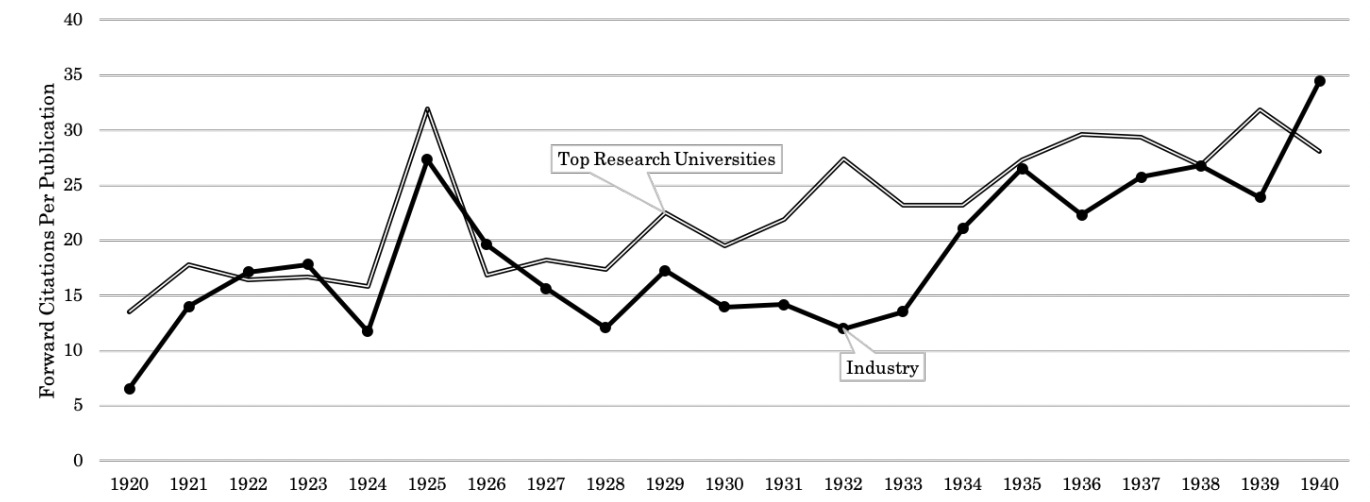

For a long period, this type of work was a massive contributor to American industrial innovation. And the MIT Corporation members were right, this type of industrial R&D required MIT to output workers that were a bit closer to hands-on scientists than practically-trained workmen with a scientific base. Industry was doing actual science in its own right. The chart below shows the average citations per publication of the top 200 large industrial firms at the time compared to that of the top 25 research universities at the time. Being the average of the top 200 firms, this graphic is not the cherry-picked results of the most famous R&D labs. There seems to have been a widespread standard of scientific rigor in the R&D labs of large firms across industrial sectors at the time.

Scientific Citations Per Publication by Sector

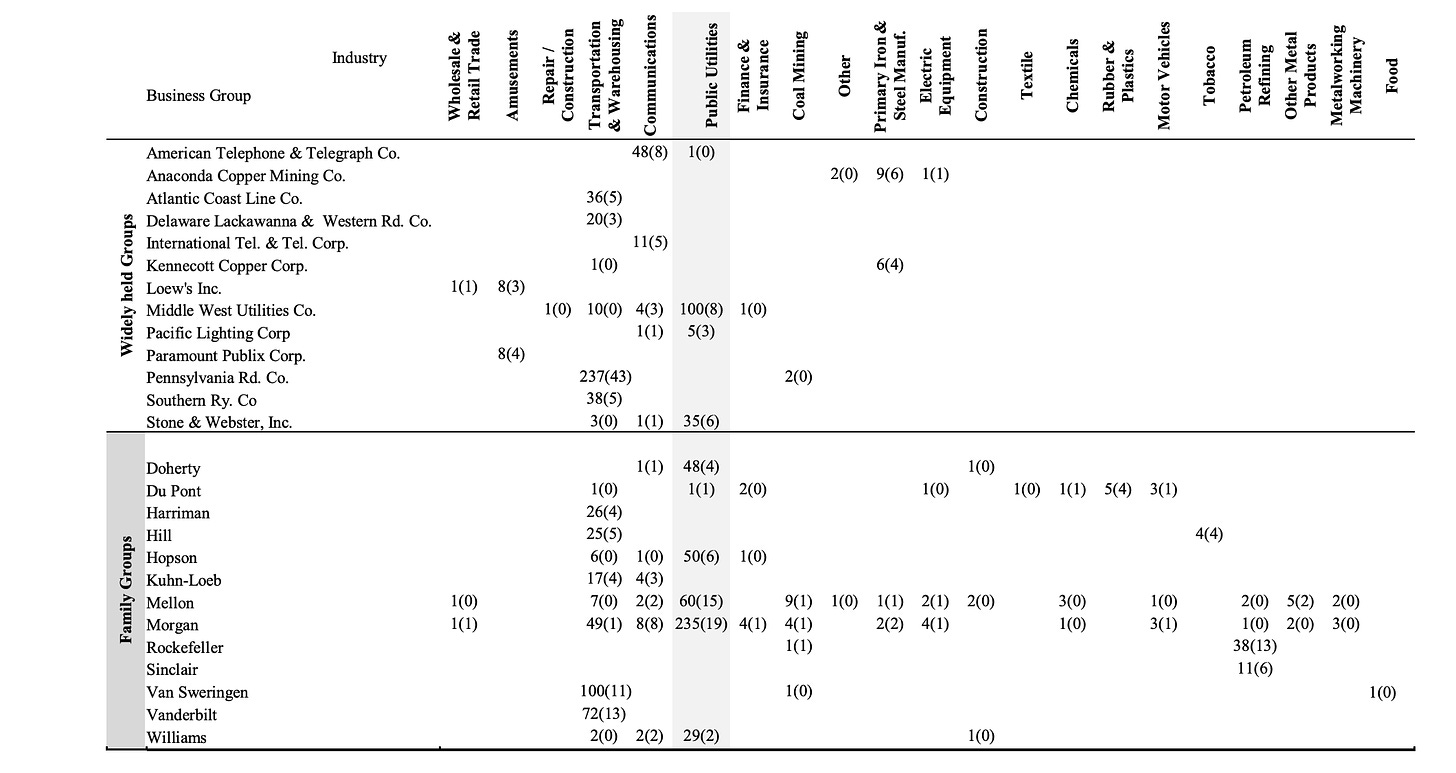

The following graphic from Candel et al. shows that these companies represented a wide variety of industries, many of them quite industrial.

(Don’t worry too much about interpreting the numbers and parentheses. If there’s numbers in an industry column, they were represented in the 200 firms in the dataset.)

This was the real-world change that Karl Compton, a practical academic physicist, was brought in by the Corporation to shape the undergraduate curriculum towards.

MIT also modified its research priorities in response to these trends

MIT researchers had been a dominant force in applied industrial research in prior decades. In these earlier decades, MIT had been hiring researchers optimally suited to this applied work and allowed them to spend upwards of half their time in direct contact with industrial partners. Compton began to prepare MIT’s research ecosystem for a world in which large industrial firms were increasingly equipping themselves with scientifically-trained individuals and the newest scientific instruments. This investment in scientific work and constant utilization of cutting-edge science meant that firms could “readily absorb the new scientific developments and accommodate university scientists in their labs.”

This had not been the case in prior decades. One noteworthy change — which was covered more at length in the last piece — was Compton’s implementation of a one-day-a-week cap on industrial consulting. Many applied faculty, Vannevar Bush included, saw this as unproductive and thought that their time allowed for consultations was needlessly being clipped down to nothing.

The policy, along with the tax on outside income that came with it, was eventually disbanded. But its mere implementation marked a turning point in the Institute’s research policies. Compton and subsequent presidents were pushing the Institute in a modified direction. The Technology Plan-era of MIT was no more. Professors would no longer be encouraged to work with industry as much as possible. Something like 20% of their time would be more preferable.

To complement this clear signal, the introduction of the time cap on outside consulting, there is written internal correspondence that indicates MIT’s leadership also had an evolving vision of what research at the Institute should look like. In talks about MIT’s mission post-World War II, Julius Stratton, who taught electrical engineering and applied physics — whose opinion was held in high esteem by Presidents Compton and Killian — wrote the following about whether or not MIT should be occupying territory increasingly occupied by industry:

Let us agree that our primary function is educational. In fact, our entire function is educational when interpreted broadly. To prevent stagnation of our teaching, to ensure a constant flow of new ideas and new material, it is essential that a vigorous program of pure research be maintained…But MIT is an engineering as well as scientific institution, and a similar argument must be made for the necessity of pushing forwards the frontiers of engineering art. Unfortunately, these frontiers aren’t clearly marked and unless we do a little boundary work I am afraid that we may easily stray over into territory occupied by industry.

Perhaps we should, on occasion, but I think we ought to know when and why. It seems to me that the excerpt cited from the charter adds to the complexity of the problem. For it states among other things that we should aid, by suitable means, ‘the advancement, development and practical application of science in connection with arts, agriculture, manufactures and commerce’ I strongly suspect that in view of the state of the arts and manufactures in 1861 the Founders mean just what they said. The development of a first-class harvester by the Mechanical Engineering Department of that epoch would doubtless have been looked upon as a practical contribution to society offsetting a lot of nonsense with test tubes and batteries, and justifying some solid financial support. Times have changed, and I submit that anyone interpreting literally that charter phrase about practical applications of science in manufactures might anticipate conflicts. As with out [U.S.] Constitution, the interpretation must evolve with the times….I do believe that it will be profitable to pursue this matter of our relation to industry further, in order to arrive at a clearer statement of policy.

Stratton did not think it was the role of MIT to continue to be a place that sought to do things like developing harvesters that could be used by farmers. While this is the sort of research work that MIT Founder William Barton Rogers himself took part in, developing methods for sanding common rocks to help Virginia farmers make fertilizers, times had changed. Stratton believed the Institute should look more like what MIT looks like today and less like its 1900 incarnation. (It should be noted that Stratton would succeed Killian as MIT President.)

Industry’s expansion into more scientifically involved R&D work, the increasing aversion of MIT leadership to engaging in too much “boundary work” similar to what was being done by industry, and the new (and ever-increasing) federal budgets for basic research in the post-war era served as fuel that pushed MIT in the direction of more pure research.

At the time, the increase in pure research and decrease in industrial research work did not seem like much of a loss to the Institute. After all, times were changing. If more and more industry innovation was happening in dedicated industrial R&D labs and less of it on factory floors, then, the thinking went, MIT professors didn’t need to play the same role in training students to be the hands-on workmen with a good scientific base that they used to. This change seemed like a better strategy for MIT to fulfill its mission of serving modern industry.

But then industry changed again…

[Most of this entire section was inspired by/drew from Arora et. al’s The Changing Structure of American Innovation.]

However, as most of the readers of this blog know, the era of the great industrial R&D labs came and went. The era had largely run its course by 1980. Among other changes in this period: Wall Street began to press large public firms to “stick to their knitting” and divest from unrelated business units, manufacturing increasingly became offshored, and managers fell out of love with managing the odd corporate entities that were these R&D labs.

The share of total applied and basic research being done by industry roughly halved between 1960 and 2015 — from around 40% to 20%. Approximately half of this drop happened between 1960 and 1980. This decline is particularly pronounced when compared to the substantial increase in size of many corporations during the era. Take IBM and GE, for example. In 1980, net turnover for IBM was around $26 billion and $25 billion for GE. In 1998, IBM’s turnover had grown to $82 billion and GE’s $100 billion. In roughly this same time period, the number of PhD-trained employees at IBM decreased from 1,300 to 1,200 and the number of PhDs at GE shrunk from 1,649 to 475.

Arora et al. describe the winding down of these research operations:

By the 1980s, however, many corporations began to look to universities and small start-ups for ideas and new products. Large corporations’ reliance on externally sourced inventions grew, and many leading Western corporations began to withdraw from scientific research (Mowery, 2009; Arora et al., 2018). Some corporate labs were shut down and others spun-off as independent entities. Bell Labs had been separated from its parent company AT&T and placed under Lucent in 1996; Xerox PARC had also been spun off into a separate company in 2002. Others had been downsized: IBM under Louis Gerstner re-directed research toward more commercial applications in the mid-90s (Bhaskarabhatla and Hegde, 2014). A more recent example is DuPont’s closing of its Central Research & Development Lab in 2016. Established in 1903, DuPont research rivaled that of top academic chemistry departments. In the 1960s, DuPont’s central R&D unit published more articles in the Journal of the American Chemical Society than MIT and Caltech combined. However, in the 1990s, DuPont’s attitude toward research changed and after a gradual decline in scientific publications, the company’s management closed its Central Research and Development Lab in 2016.

The paucity of large firms winning R&D 100 awards is another indicator of this change. In 1971, Fortune 500 firms won 41% of these awards. In 2006, this number was down to 6%.

The world had changed again. But MIT did not necessarily revert to its older educational and research practices to better serve industries that had reduced their scientific efforts and lost a substantial amount of their scientific know-how. Some modern industries, such as those related to Silicon Valley, do maintain somewhat similar labs. Other industries, such as bio and biotech, conduct different aspects of this golden-era type corporate R&D in university spinoffs, startups, and larger companies. Other industries, conversely, have reverted to a state of R&D that is more similar to their early-1900s counterparts, but now without an early-era MIT to collaborate with.

MIT 2.0

The marked reduction in certain industries’ scientific know-how did not seem to affect the Institute’s view of its place in the world or the kinds of research it produced. As far as I can tell, to this day MIT is mostly seen as a place of pure research, but with a more technological bent than other universities. Its professors in many departments are still encouraged to spend about — but usually not much more than — 20% of their time working with industry. Its students do not tend to go work in hands-on professions and are closer to what Jewett described Bell Labs requiring of MIT graduates in the late 1920s:

Not so much practical skills as graduates broadly educated in science, mathematics, and basic engineering principles—personnel with minds open to “the anticipation of technological change…some contact with the spirit and methods of research, and preferably some experience in it, so that [they] would be prepared to grasp new technological opportunities and either to participate in their development or at least to understand something of the conditions required for such development.”

And there are still many industries that need graduates exactly like this. Tech firms have, to a significant extent, retained the mid-1900s culture of the industrial R&D labs. Many employ large numbers of highly skilled engineers and PhDs doing mission-oriented work that builds on scientific insights that serve the businesses’ ends. In addition, the life sciences/bio/biotech spaces come to mind as areas in which the large firms and startups alike, in different ways, embody different aspects of the old-school industrial R&D labs.

Not surprisingly, MIT alumni stream into all of these industries and are likely among the highest performers in them.

And that is great for those industries, but it seems clear that areas like construction and manufacturing have lost out in all of this. The Compton era was when majors like mining engineering, sanitary engineering, and construction engineering were phased out of the Institute’s curriculum.

MIT as a place for hands-on, learning by doing is by no means dead. But the Institute, in many obvious ways for those who have read Part 1, has de-emphasized these skills in many ways. When MIT became a place that saw the practical work of granting degrees in mining engineering or doing research to make first-class farming harvesters as not in scope with its mission, it stood in very stark contrast to the MIT described in the first piece.

But it makes complete sense how the Institute got from where it was to where it is today. Abruptly shifting back from a place of technologically-focused pure research to a place that once again focused on the training of scientifically-savvy but still hands-on workers would have been a tall task. Not to mention, MIT was already clearly a world leader in what it was currently doing.

But that does not make it any less true that the industrial sectors that are not widespread employers of top scientific talent and who do not heavily invest in golden-era R&D lab-style research need an old MIT more than ever.

Hope you enjoyed. 🙂

End Notes

The following is an excerpt that I couldn’t slide into the piece but that readers might find interesting. It helps the reader understand the tradeoffs that the Institute was attempting to navigate for several decades.

Philip Alexander wrote of an episode at the Institute in the late 1920s:

The growing emphasis on research and graduate education led some to wonder if ‘the Institute now regards itself as primarily a research institution where a faculty man’s hopes of promotion varies distinctly with his publication output [and where] classrooms become discouraging affairs, supervised by men who do not, in general, dare to allow teaching become a primary interest.’ Stratton’s position was that without the research mindset, faculty members risked becoming “mere routine men” out of touch with their fields. But some corporate interests worried, too, about MIT losing sight of the ordinary engineer. One executive told Stratton [the then President about to pass the reigns to Karl Compton] that he wanted to support ‘some university that is not trying to make science abstruse and difficult to understand, but one that believes as I do, or one to whom I can sell the idea that the greatest contribution that all of us can make to science is to make it so simple that it can be understood by the mass of our people and its benefits applied by all kinds of people and in everyday problems.’

I will complement this story with a story from my own undergrad experience. One of our beloved data science TAs at Stanford was not just a genius, but also a fantastic teacher. He had done his undergrad at MIT. He had mentioned many times how much he liked Stanford’s CS curriculum. One day, when we pressed him for details as to why, he kind of sheepishly smiled and said something like, “Um…uh…Stanford’s CS curriculum is much more…uh…approachable.”