by Eric Gilliam

Executive Summary: Early MIT was a remarkably differentiated product from the other elite universities of its day. The Institute saw its mission as being, first and foremost, to serve the needs of industry. And the primary mechanism it leveraged to do this was an engineering education that married the hands-on, technical training of trade schools with knowledge of the scientific principles relevant to ones field. This created engineers who had experience in the production process on the level of a foreman, but who were also endowed with the engineering and scientific education that allowed them to accurately troubleshoot and overcome a variety of technical problems when in the field. It was this education that was likely responsible for MIT’s alumni being able to thrive in vital engineering roles in America’s era of peak economic growth, an era whose growth is largely credited to engineering and technical feats. This is a style of education that individuals and organizations interested in innovation in the world of physical things should look to recreate to help generate more progress.

The MIT Series

Patrick Collison and Tyler Cowen opened their 2019 Atlantic piece that helped jump-start the progress studies movement with the following passage:

In 1861, the American scientist and educator William Barton Rogers published a manifesto calling for a new kind of research institution. Recognizing the “daily increasing proofs of the happy influence of scientific culture on the industry and the civilization of the nations,” and the growing importance of what he called “Industrial Arts,” he proposed a new organization dedicated to practical knowledge. He named it the Massachusetts Institute of Technology.

In my eyes, MIT is entirely deserving of this honor: being used as the authors’ first example of an organization that generated progress. Yet, despite how well-known this article has become and MIT’s prominent placement in it, many in the progress studies community still don’t appreciate just how different the Institute was in its early years — arguably the Institute’s most productive years.

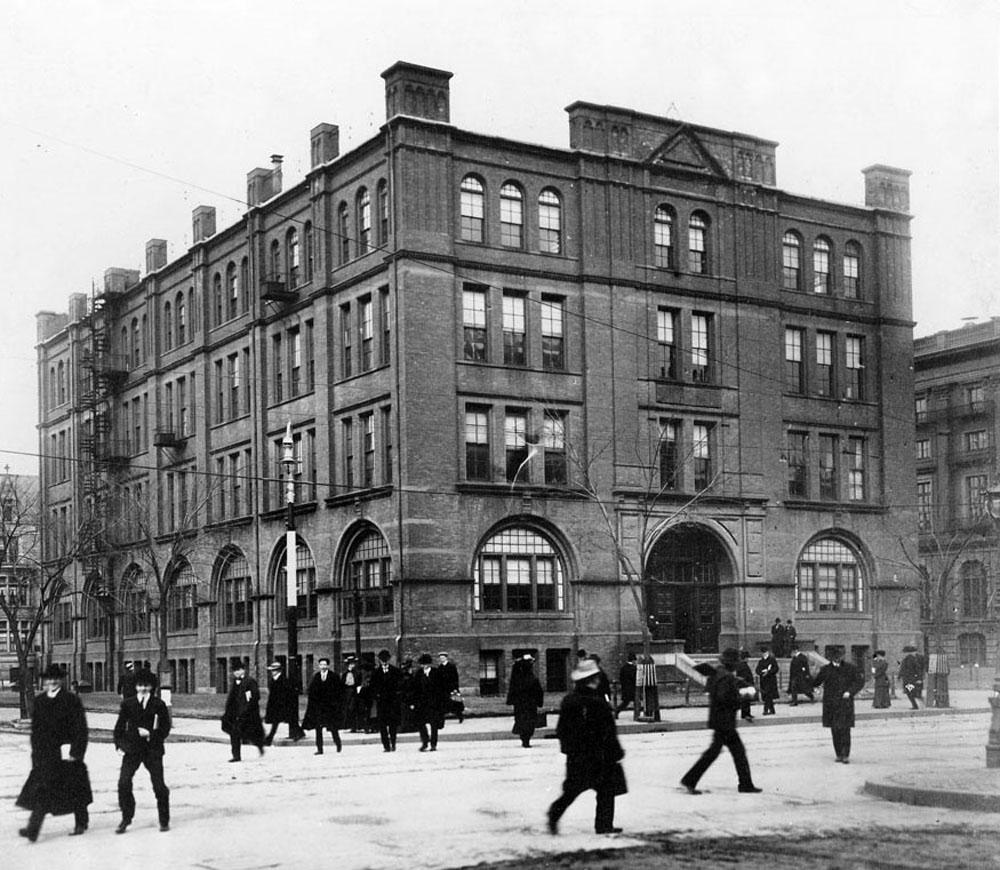

Early MIT was a remarkably differentiated product from the other elite, Ivy League universities. It was an experimental school focused on training a new kind of technical man, and a remarkably successful one. It helped train many elite engineers who helped build the country in America’s era of peak economic growth, an era whose growth is largely credited to engineering and technical feats. And its faculty contributed to this growth in an even more direct way, undertaking courses of research that bordered on being so practical that many in modern times wouldn’t even call it real academic research — not to mention its extremely close Industry partnerships that the school saw as vital to its mission. MIT was a place that saw itself as existing in service to industry, and it thrived in that role.

Over the next three pieces, I hope to help those who are less aware of MIT’s early history understand what the Institute did that made it unique. The three pieces will cover:

- How MIT trained its students (usually engineers)

- The early philosophy responsible for MIT’s extremely applied research projects

- How the university began its drift, resulting in a school that is much closer to other elite research universities than to the hybrid technical school/applied research institute that it used to be

In this piece, I start the series where William Barton Rogers would have wanted it to start: detailing the education that went into building a ‘Tech man.’* But, before I dive into the educational process that made tech men, I’d like to give readers an idea of what early ‘Boston Tech’ alums were going on to build using the skills they gained at MIT.

*As a note, much of the MIT-specific information in this piece come from Philip Alexander’s fantastic work of history called A Widening Sphere: Evolving Cultures at MIT.

* Throughout the piece, I will utilize the term “Tech man” as it was one that the school and alumni continually used as something of a cultural marker for the kind of differentiated workers they were creating. An example of the term being used in context is in the following quote in which Coleman DuPont replies to someone who thought the Institute’s professors shouldn’t compete with its own students for consulting contracts. He swatted this fear aside, saying ”If any Tech man has made such a criticism, he must be a poor specimen of the breed, for the real Tech man has no fear of competition.” Women would, in fact, attend the Institute in small numbers or as special students for much of the late 1800s, which was quite progressive for the time. But it would be many decades before they were true equals at the Institute and many more before they attended in roughly equal numbers.

Tech Men: The differentiated results

As long-time MIT Chemistry Professor Arthur Noyes (’86) once put it, the Institute aimed “to produce men who have the power to solve the industrial, engineering, and scientific problems of the day — men who shall originate and not merely execute.” Many tech alums would go on to do just that on the scale of individual factories and industrial operations. This was the use case that the Institute likely had in mind for its early graduates. But, as time went on, many others would find themselves in positions to do this at scale not just by working in leadership at massive firms; but, also, by finding themselves at the helm of some of the great industrial R&D labs with which many in the progress studies community are all-too-familiar.

The era of the great industrial R&D labs was built, in no small part, by MIT men.

Arthur D. Little

The first of these pioneers was Arthur D. Little (’85), who was a trailblazer in the new era of industrial research. He worked for a period at a paper mill, starting as a chemist and later becoming superintendent of the mill—a common career path for MIT alums at the time. Then he struck out on his own to start an independent firm with one of his co-workers from the mill, Roger Griffin. This firm would specialize in chemical analyses for quality control. He later applied his skill set to other problems, such as finding a way to make film that provided an alternative to the flammable nitrocellulose film, which would frequently set fire to cinemas filled with people.

His most important venture came with the firm he later founded, Arthur D. Little, which had its first major success in 1911 when General Motors tasked Little with setting up and staffing the company’s first-ever centralized R&D department.

Little and his firm would go on to apply this industrial research skill set to seemingly any industry which was willing to seek out their services—which was many. As Claudia Flavell-While wrote:

With this success under his belt, more scientific research and process design tasks followed, spanning smoke filters, newsprint, producing alcohol from wood waste, recovering turpentine and rosin from pine-tree stumps, and even airplane dopes. By 1918 the company occupied its own building in Memorial Drive, Cambridge, and had completed more than 16,000 separate investigations.

What had begun as a simple analytical laboratory had progressed into a serious industrial research operation, where different specialists in different departments would work together to fully exploit every promising breakthrough by fundamental research and thorough investigation of all the potential industrial applications for their economy and practicality.

Little believed that good chemistry and chemical analysis were the most direct way to boost efficiency in industrial applications of all kinds. “Every waste that is prevented, or turned to profit, every problem solved, and every more effective process which is developed makes for better living in the material sense and for cleaner and more wholesome living in the higher sense.” He was a pioneer in helping make this mindset more accepted in industry.

Little pulled no punches when criticizing many of the major educational institutions of the day.

It must be admitted with regret that our […] institutions of learning have failed to seize or realize the great opportunity confronting them. […] They have, almost universally, neglected to provide adequate equipment for industrial research, and […] have rarely acquired that close touch with industry that’s essential for familiarity and appreciation of its immediate and pressing needs.”

DuPont Research

Alongside Bell Labs, the Dupont research division is regarded as one of the great dragons of this golden era of corporate research and development. Arora et. al wrote in The Changing Structure of American Innovation that DuPont’s “research rivaled that of top academic chemistry departments.” They also noted that, In the 1960s, DuPont’s central R&D unit published more articles in the Journal of the American Chemical Society than MIT and Caltech combined.

(Dupont’s research unit would also add a Nobel Prize to its name in the coming decades. The award would go to Charles Pedersen, one of the few laureates without a Ph.D., who also happened to have obtained a Master’s in Organic Chemistry from MIT in 1927)

Not so coincidentally:

The DuPont family, industrialists of Delaware, sent its sons—William (’76), T. Coleman (’84), Alfred (’86), Maurice (’88), Pierre (’90), Henry (’94), Irenée (’97)—and a host of their descendants would follow, making Tech a family tradition. — A Widening Sphere

T. Coleman, Pierre, and Irénee would all serve as company Presidents in the coming decades. While some might believe that any family that would send that many of its sons to MIT may have set up a great industrial R&D lab whether they sent their sons to MIT or not, I don’t think it is a coincidence that DuPont research was established in 1903, the year after T. Coleman DuPont took over as President. T. Coleman, a Tech man and the first of three successive MIT alums who would run the company, took over after the sudden death of Eugene DuPont, a UPenn alum, after his 13-year tenure as President.

Eastman Kodak and MIT

Eastman Kodak was a powerhouse employer of top scientific talent throughout the 1900s. If you’re curious just how in-depth the research behind a company like Kodak’s product offerings can get, I encourage you to read this 1949 Nature excerpt of an exhibition put on at one of Kodak’s labs.

While George Eastman did not go to MIT, he was an appreciator and hirer of MIT alums to an extreme degree. Not only did his top aid — and eventual Kodak President — Frank Lovejoy (’90) attend the Institute, but he made a point of hiring MIT men in very high numbers. He saw MIT as the top hunting ground for technical talent. An MIT man oversaw the construction of Kodak’s original plant and managed the operations of the plant for almost a decade. In the early life of his R&D department, which would grow to contain thousands, the department was staffed with many MIT alums.

In January 1912, then-current MIT President Richard Maclaurin was on a promotional tour on behalf of the Institute and was invited to take his longest stop on the tour at Kodak’s headquarters in Rochester. Eastman missed Maclaurin on this trip, but he seemed genuinely disappointed and asked Maclaurin to meet him in New York City when the tour was over. The two met for a drink at a hotel in New York City. It was their first time meeting. The next morning, Eastman pledged $2.5 million to MIT. This amount of money was by far the largest ever contribution to the Institute and far more than they had been receiving from the state of Massachusetts.

Maclaurin was confused. A donation of this size was not even his goal.

Flabbergasted, Maclaurin made his way back to Grand Central. On the ride home, he played out the scene over and over. Almost too easy—no probing, little discussion, few questions, no pre-conditions. — A Widening Sphere

Eastman was not looking for fame either. He requested his giving remain anonymous. He would continue to write the Institute extremely large checks, as needed, for decades.

He was just a fan of the Institute and felt he had benefited greatly from its product.

General Electric’s Research Laboratory

Willis Whitney (’90), an MIT alum and instructor, was the founding Director of General Electric’s Research Laboratory. The now-famous lab would go on to make countless discoveries that were vital to GE’s business, and oftentimes science as a whole. William Coolidge (’96), an MIT alum and researcher at the lab, conducted the experiments that led to the use of tungsten as a light bulb filament. If that weren’t enough, he later used this technology in his work for GE that made improvements to X-Ray technology that are still relevant today. Coolidge later became GE’s lab director himself.

The lab was founded in 1900, and by 1906, the size of the lab had already grown to over 100 staff. By 1930, the lab contained over 400 physicists, chemists, electrical engineers, and support staff. On top of being invaluable to GE’s business, the lab would even go on to win two Nobel prizes. One of these prizes, won by Irving Langmuir in 1932, helped lead to the technology for gas-filled light bulbs that allowed GE to muscle its way to an astounding 96% market share in incandescent light bulbs.

Thomas Edison held MIT in high-esteem

Thomas Edison was an extremely practical man, particularly for someone as off-the-charts inventive as he was. Edison loved science and scientists. One of his idols was Maxwell. He, daily, perused a wide variety of scientific publications to stay current on the applicable theories, practical experiments, and discoveries. But all of this was with a purpose. He used science to invent. And he invented with a purpose: to make things that could be profitable and that people would pay him to produce at scale.

When Edison learned that Einstein didn’t know the speed of sound, and had replied that he didn’t care to clutter his brain with facts that could easily be looked up in a textbook, Edison stated that he hoped his son Theodore (’23), who studied math at MIT, would not lapse into this impractical mindset.

Theodore is a good boy, but his forte is mathematics. I am afraid…he may go flying off into the clouds with the fellow Einstein. And if he does…I’m afraid he won’t work with me.

Valuing practicality, scientific inspiration, the experimental process, and inventiveness the way he did, MIT was a school after his own heart.

Edison, an avowed critic of the university system and what he saw as the mediocre technical workers it produced, told an MIT alumni banquet once that “more nearly than any other school or college in this country, the Massachusetts Institute of Technology meets the demands of modern American life.” Edison sent two of his sons to the Institute. And he sang MIT’s praises frequently. In the same year, 1912, Edison was quoted by the Yale Daily News lashing out at traditional colleges and in favor of Tech: “I would employ almost any graduate of that institution who came to me,” he told the interviewer, but “in my business, if a Yale or Harvard man should come to me for employment I should probably say that there was no place vacant.” To be clear, he said that to the face of the Yale Daily News reporter. At any given time, Edison counted 30 or more Tech graduates in his enterprise with only a handful of hires from the famous liberal arts universities.

The professors at MIT tended to love Edison back. He was everything they were trying to train Tech students to be: scientifically informed, good with their hands, able to apply the combination of those tools to a variety of problems, and practical. When the Institute was looking to put the names of great scientific minds on the inside of MIT’s dome, the professors were upset to learn that the current president would not allow the names of living scientists. That meant the name of a great American would not be included. If not for the rule, Edison’s name would have been up there with names like Newton and Galileo. To a modern ear, his placement with those scientific greats might sound strange. But, to a contemporary Tech man, it made perfect sense. The Edison-like blend of scientific knowledge and workman-like know-how is the bedrock of industrial innovation and exactly what the Institute existed to help facilitate.

MIT took pride in the hands-on nature of its workers

While the above recounts the contributions of tech men to the great labs that did scientifically inspired inventing and innovating full-time, it was more typical for MIT alums to go work in an environment that was more hands-on and industrial. Mining, building roads and railroads, power production and distribution, chemical manufacture, public health, sewage, and sanitation were common industries alumni went into. And they often worked their way into roles as foremen, superintendents, or internal innovators/troubleshooters for these operations quite quickly.

The Institute did not train engineers to primarily go seek employment in the major cities like many modern universities tend to do. A country was being built up and connected, and MIT wanted Tech men to go lead the charge in this building. Tech alums were known to seek employment anywhere from the densest cities to the most remote outposts. In the early decades of MIT, many prospective students had heard about the school as a result of the many alumni who were working on and in charge of building sections of the railroads being built all around the country. As Alexander wrote:

Some lived as itinerants, moving from spot to spot, from one specialty to another, as industries shifted locale or focus, or as new settlements emerged. Tech graduates were known as adventurers, risk-takers, explorers inspired as much by a thrill or a challenge as by a safe income or job security. — A Widening Sphere

The Institute and its students understood that the common problems of industrial life mattered and required an individual who understood the production process as well as scientific and engineering principles to overcome them. Even those who went to work in areas that had a less hands-on, industrial feel, like the famous R&D labs described above, benefited from this skill set.

Here is a Wikipedia excerpt describing the first project that Willis Whitney worked on with General Electric. It was the kind of problem many MIT alums would encounter and solve in plants all over the country:

One of the first problems Whitney solved at the General Electric Laboratory was that of making a furnace that produced porcelain rods with scientific precision. He noticed that many rods would go to waste because of various defects.[1]After consulting with a foreman, he found that the current furnaces had varying temperatures; especially after a certain amount of repetitions. As a result, the furnaces could not be expected to produce perfect porcelain rods after every attempt. After experimenting with iron pipes, carbon pipes, and wire, Whitney found that he could create a suitable furnace by passing a controlled amount of current through a wire wrapped around a carbon pipe.[3] The carbon pipe would have a cork or coal powder in it to prevent combustion and water-cooled clamps to regulate the temperature. After finding the perfect ratio of heat to time cooking the porcelain rods, Whitney called in the foreman. Whitney demonstrated that the porcelain came out perfectly nearly every time and G.E. began production of the furnaces immediately.

This was a classic use of an MIT brain at the time. Whitney was trained in MIT’s workshops to understand the hands-on context that a foreman works in, and was also endowed with the kind of engineering training and classroom science that would allow him to both come up with and rig up a solution to a problem like this. But, crucially, he would likely have never learned about or cared about this application of his knowledge — making slightly less imperfect porcelain rods — if he wasn’t put in a position where he was in direct contact with a foreman making the rods and observing the production process itself. Luckily, this was the work environment MIT tailor-made its curriculum for and placed students into.

Tech men would also make notable contributions to companies with high-tech-feeling outputs like those in electronics at Bell Labs, Hewlett co-founding Hewlett-Packard (Master’s ‘36), Cecil Green (’24) co-founding Texas instruments, and Wong Tsu being the first engineer at Boeing (’16). But, crucially, MIT did not see accomplishments like those as a higher calling than working on the technically complex means of production for what felt like a simpler output, such as a porcelain rod. It is so easy to forget that anything with a high-tech process is a tech company, regardless of how low-tech the output may seem—such as paper. And these companies need extremely smart, skilled workers in the weeds of how the production process works while also being trained at a high level in useful scientific principles. These individuals enable an operation to continuously find problems and be able to solve them.

A famous example of an MIT alum showing this same style of ingenuity to make a low-tech-seeming output possible happened in the design of the famous safety razor. The Gillette company may not have been possible without MIT alum William Emery Nickerson (’76). King Gillette had the idea and the patent, but there was no practicable way to press steel in such a way to make the design workable. That is, until Gillette described the problem to Nickerson, and Nickerson, after some experimenting, figured out just the tricks (see patent images here and here).

As another example, Arthur D. Little did eventually leave his role at the paper company to do chemical analysis, quality control, and troubleshooting for more than just his one employer. But, for every Arthur Little who made a name for themself on a larger scale, there were hundreds of solid MIT workers doing that effective style of work for individual employers around the country. The continuous involvement of workers trained in scientific principles and experimentation who, daily, work with the production process at the level of a foreman or line worker is how real innovation in physical things and processes tends to happen.

MIT designed its education with the specific goal of producing engineers like those named above. And, hopefully, this section gave the reader an understanding of what their results looked like.

Now, with all of that on the table, let’s talk about the education that built these men.

Tech Men: The differentiated education

In the mid-1800s, commercial interests in Massachusetts had been yearning for an effective school of applied science that could train men for regional and local needs. Except for Rensselaer Polytechnic Institute, the other efforts in this area had proven disappointing. Examples of these disappointments include Yale’s Sheffield Scientific School and Harvard’s Lawrence Scientific School. Alexander described Harvard’s Lawrence School at the time in a way not dissimilar to how many would describe the faculty in top university technical departments today:

Lawrence’s faculty…was composed for the most part of men who lacked interest in the applications of science; their primary focus was knowledge for knowledge’s sake, reinforced by institutional cultures where the useful, the practical, the vocational, the “merely” professional, were looked down on. Study science, yes, but its practical side belonged in the trade schools. — A Widening Sphere

Rogers knew that was a remarkably poor approach. Professors who are not steeped in hands-on industrial practice could not produce the kinds of workers that were immediately useful to industry. These schools were outputting the kind of men that Edison, and many others mentioned above, did not believe were meeting the needs of industry. And the technical know-how taught in trade schools was great, but an ideal institute of technology should also impart some higher engineering and scientific knowledge to students to enable them to be more innovative, intelligent problem-solvers.

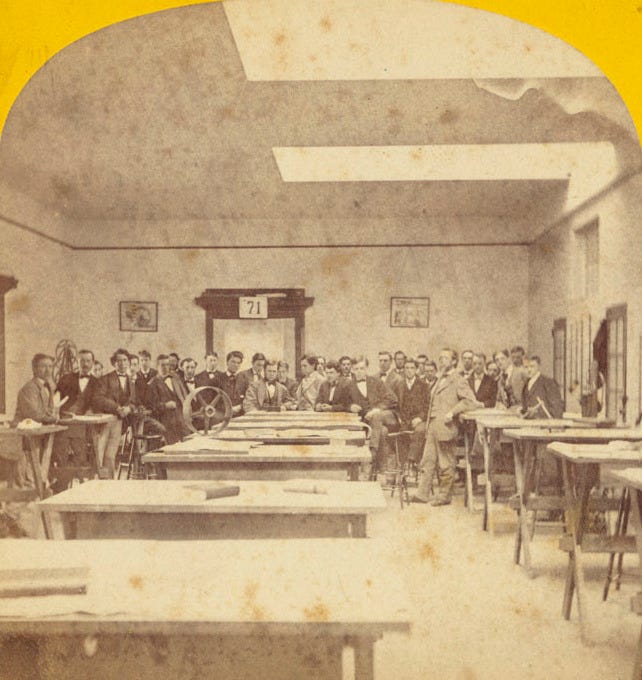

So, MIT was founded to solve this problem. This school was not designed to be a place for purely lecturing and rote learning. A smattering of intelligent men from industry and university men with an applied bent to them made up the original faculty. Content was lectured as needed, but what differentiated MIT was its innovative use of the laboratory method. Instructors taught “through actual handling of the apparatus and by working on problems, shoulder to shoulder with the boys.” And the schedule, from 9-5 (with a lunch break) 5 days a week and additional class on Saturday was meant to simulate a normal work schedule and, thus, ease the eventual transition to life in the working world.

The school had humble beginnings with simple classroom and workshop spaces. In many cases, there was only one of each kind of a certain piece of equipment in the workshop. So, for hours on end, students would ogle and comment over each others’ experiments as they waited their turns to do their experiments.

At first, the Institute only offered five majors

- Mechanical construction and engineering

- Civil and topographical engineering

- Building and architecture

- Practical and technical chemistry

- Practical geology and mining

And the students who came to study at the Institute were quite diverse for the time. Some would have otherwise studied technical subjects at a place like Harvard and others would have just gone straight to work in the New England Factories if not for the Institute.

Rogers brought sons of factory workers, laborers, blacksmiths, janitors, and hackney drivers together with upwardly mobile offspring of bank clerks and factory managers, together with heirs of vast family fortunes, privileged Brahmins whose families had built Boston from scratch. — A Widening Sphere

Some of these great Boston families, often made up of largely Harvard-educated men, were sending their children to MIT because they had grown concerned about the relevance of Harvard’s curriculum in this period of rapid industrialization.

Even the ads and flyers advertising the school made no efforts to pretend this was some kind of university. They were proud of advertising it for what it was.

Some…had heard about the school from friends or family; a few had seen ads in the local papers announcing a four month course in ‘Mathematics, with practice in Geometric Drawing, and Shading in India Ink,—Lessons in Descriptive Geometry, illustrated by a suite of models in relief. Physics, including elementary doctrine of Forces, and Mechanical properties of Solids and Fluids, accompanied by Manipulations. Chemistry of the Inorganic Elements, with Manipulations. Practice in the use of the Plane Table, Level, and Geodesic Circle. Free Hand Sketching. The French Language (necessary to read technical journals of the time).’ These men were practical fellows in search of a curriculum more useful, more marketable, than what Harvard had to offer. — A Widening Sphere

Boston Tech was not a place for those who considered science and technology on a lower order of learning than Latin, Greek, or history. And the math here was learned for entirely practical purposes.

The coming decades would see some slight changes to the mission based on who the president was and the funding situation, but throughout the first 70 years of the Institute, the President and most of the faculty remained quite attached to the primary goal of the Institute being: the education of men that were extremely useful to modern industry, whatever modern meant at the time. In William Barton Roger’s farewell speech to the Institute in 1882, in which he planned to pass on the Presidency to Francis Walker, he noted, “Formerly a wide separation existed between theory and practice; now in every fabric that is made, in every structure that is reared, they are closely united into one interlocking system,— the practical is based upon the scientific, and the scientific is solidly built upon the practical.” He died while giving this speech, but his vision successfully lived on.

‘Not a place for boys to play’

Under new management, the Tech men continued to work hard. Tech’s schedule worked students significantly harder than the liberal arts colleges of the day. Even after the 9-5 work schedule — which often involved not just large amounts of time spent in the classroom, but substantial time spent doing physical labor to learn the skills of their trade in the workshops — students would then spend most of the night preparing for the next day’s workshops and coursework. As one said, “Men go to Tech not to have their alma mater seal them gentleman, but to make them workers.” F. Parker Emery, who had taught both at Tech and later at Dartmouth said that Tech men worked twice as hard as Dartmouth men and admiringly said of Tech’s high standards that it operated on the “law of the survival of the fittest.”

When alumni were surveyed in the late 1800s, they deemed themselves thankful for this tough but effective training. Boston newspapers would continually drag the institution as a place that worked students to an unhealthy level. To one of these articles, written in 1890, President Francis Walker retorted, “The Institute of Technology is not a place for boys to play, but for men to work.”

President after president proudly fended off sports that would be all-consuming to students such as football. If any student wrote asking about such things, the presidents would kindly inform them that MIT was not the place for students harboring dreams of top athletics. There just should not be time or energy for such things, not if students were working hard.

The Institute made a habit of purchasing as much industrial and laboratory equipment as they reasonably could to allow the students to train in conditions as similar to industry as possible. Additionally, MIT would make a habit of keeping an irregularly large proportion of its instructors as part-time instructors who, during the day, held jobs in industry — and were quite intelligent. This seemed to just be common sense given the goal of the Institute. In addition, the Institute encouraged its full-time faculty to spend a fair amount of time contracting with industry to keep abreast of the current best practices and trends so they could teach the students as effectively as possible.

While the Institute was only growing slowly in the early decades, it was clear that its alumni were meeting the needs of industry and more. As students began to graduate and gain industry experience, the Institute began to bring on high numbers of its best alumni as instructors. Many outsiders felt that this betrayed a bit of an internal bias, but the Tech alums thought this just made sense. The Institute had a unique curriculum. In their eyes, Tech alums proving themselves to be the best applicants to teach it was just a sign of the education working.

Working upward, reaching downward

Tech was always looking to do more research, but, in the early decades, this priority often fell by the wayside as resources were extremely limited and the top priority was always educating students. But, around 1900, Tech began to take more substantial steps in this direction with the opening of three successful labs. (I’ll speak more on the research functions of all of these labs in the next piece.) The educational component of these applied labs was quite important in the Institute’s eyes to optimally educate the students to be the level of problem solvers the Institute hoped to produce. One of these labs was the School of Engineering Research which was established to allow advanced students a place to work, experiment, develop ideas, and possibly publish in engineering-related disciplines. And while the Eng.D., a doctorate in engineering, would be offered, the focus was to be on the research and not the credentials. (This particular lab would end up shutting down due to staffing constraints, but the Institute would successfully offer learning opportunities like this to students in the coming years.)

Meanwhile, tech was also doubling down on its mission of professional/practical usefulness. The goal was for the Institute to begin to “work upward” towards some kind of research excellence, in its own way, and to simultaneously do work that “reached down” to serve the needs of “men who stand between the unskilled worker and the engineer.”

In the same time period in which President Pritchett was pushing for the creation of these labs, Tech professors would also often be expected to teach night lessons to local tradesmen on industrial design and practical mechanics. The Tech professors, finishing up their workday, would meet the tradesmen, who had just finished their workday, for an evening of lectures, recitations, and lab experiments. As Alexander wrote:

The students, all men, came from service jobs in industry. From motormen to machinists, electrical workers to draftsmen, they ranged in age from teenagers to fifty-somethings. The teaching staff, also coming off a full day’s work, got extra pay for staying on at night. Many were less interested in the income than in the notion that this would benefit the community and that it would keep them abreast of changing conditions in local industry. Pritchett viewed the program as an affirmation of Tech’s hands-on tradition. — A Widening Sphere

Individual MIT Presidents each had their own new ideas about how to best build symbiotic ties with industry and train the students. President Maclaurin, who succeeded Pritchett in 1909, began a program in chemical engineering intended to link the curriculum directly with industry. Students were assigned to different ‘stations’, usually a company plant or factory, to gain hands-on experience in various processes and production methods. Various local companies allowed the students hands-on experience in processes such as: paper manufacture with the Easter Manufacturing Co., electrochemistry with the Carborundum Co., high-temperature processes with New England Gas & Coke Co., dyes with American Synthetic Color Co., and grinding and crushing processes with Atlas Portland Cement Co. In the following years, a similar program in electrical engineering was set up in partnership with General Electric. An industrial biology option was also later added.

The solidifying reputation of the Institute

Around the time when President Maclaurin took over, it was becoming clear that MIT had built something special — to New Englanders as well as those in other regions.

Upon taking office in 1909, Maclaurin compiled a record of the Institute’s role in national, state, and municipal development. The list included nearly a hundred items such as: power transmission, telephone technology, locomotive efficiency, control of steel and iron corrosion, recovery and disposal of industrial waste, reinforced concrete, fire-resistance, synthetic rubber, sewage management, traffic control, and more. With this list, Maclaurin was able to convince the state to quadruple the size of the yearly grant. And this was an impressive feat given that previous presidents had often failed to get extensions to previous grants or increases in size.

And other regions saw the value of MIT as well. When they heard MIT was pleading for a larger tract of land in 1911, other regions were willing to bend over backwards to attract the Institute to leave Boston. They believed MIT would likely bring with it substantial improvements to their regional industrial capacity. Springfield, Massachusetts offered a free 30-acre tract of land for the Institute and a merger between Worcester Poly and Tech—with extremely favorable terms for Tech. The Chicago Evening Post, the local paper of the industrial powerhouse that was Chicago in that era, ridiculed Boston for not appreciating what it had: “We could support a ‘Boston Tech’ with our loose change, and we wouldn’t, like some cities we know of, have to search all the hinterland roundabout to find the money.” They couldn’t believe that an obvious industrial force-multiplier like Tech had to grovel the state for small amounts of money every few years.

The money eventually did come, mostly from Coleman DuPont. Some raised concerns that the patch of land the school chose was of poor quality and that the new buildings might sink into the soil. That was the main reason that many had overlooked that particular piece of land for years. Maclaurin understood these concerns but was largely unconcerned. He was a proud father of the Institute and its outputs. These were the kinds of technical problems that Tech trained men to figure out and overcome. It would be fine.

(To this day, the Institute’s buildings, to my knowledge, have not sunken into the ground)

The start of Tech’s military ties

Around this time, the military also began to appreciate the extreme applicability and effectiveness of the MIT curriculum. Prior to this point, the military academies had possibly the best practical technical education that could be found. But during World War I it became clear that MIT was now head and shoulders above the military academies in many areas. After a conversation with President Woodrow Wilson in which Maclaurin had shared his theories about modern warfare being 90% engineering, he had piqued Washington’s interest in the Institute as having strategic military value.

Maclaurin’s theory intrigued Wilson’s Secretary of War Newton Baker, who appointed a board to survey the Institute’s course offerings and to assess what the military branches might gain from them. The board’s report, issued in March 1917, called MIT’s resources in several areas—civil, sanitary, mechanical, electrical, chemical, and engineering administration—remarkably impressive, far better than those in the military academies. In addition to recommending that members of the Reserve Officer Crops be required to take MIT courses whenever possible, the report also urged the Institute to devise additional courses of a shorter, more specialized type—the chemistry of explosives, for example—which officers could be assigned to register for on a limited basis

When war was officially declared on Germany in 1917, Maclaurin was eager to ensure the Institute did as much as it could to serve the nation. MIT committed buildings, personnel, equipment, and other resources to the government. “The campus shifted from civilian to military purposes overnight.” Buildings and offices turned into makeshift barracks. Special schools of aeronautics, naval aviation, engineers and navigational officers in the merchant marine, naval architecture, sanitation workers, and more servicing as many as 300 students at a time. Many professors, being quite effective engineers themselves, were sent out to run complex engineering field assignments. These were common assignments for the civil engineering and sanitary engineering professors who proved very useful to the military in these roles. The school’s labs and professors were enlisted for research work as well (more of which will be covered in the next piece).

The army seemed quite happy with this relationship. They would continue to enlist Maclaurin for other services for years, such as setting up a bigger Student Army Training Corp since he had done such a fantastic job with the services on MIT’s campus. And they would double down on their intensive partnership with the Institute when World War II came around.

Evolving to stay useful

MIT always strove to meet contemporary industrial needs, so its curriculum expanded to serve new industries. By the end of the 1800s, the number of majors had expanded from the original five to also include electrical engineering, sanitary engineering, naval architecture, chemical engineering, geology, biology, and physics. And, it should be noted, that MIT’s biology major was not exactly what many readers would associate with a modern biology curriculum. The major consisted heavily of sanitary science, bacteriology, epidemiology, and industrial biology. Sewage disposal, air and water quality, plant and human diseases, food preservation, and fermentation were some topics of major importance.

New majors would often branch off from the common combination of two existing majors if it became clear that they were extremely complementary. President Walker demonstrated impressive foresight in the late 1880s, in creating the sanitary engineering major, when he noticed, “the increasing necessity for co-operation between the engineer, the chemist, and the biologist, in dealing with questions affecting public health.” Similarly, chemical engineering grew out of the chemistry major. Chemistry, initially, consisted of an organic and industrial track. The second track eventually broke off to become chemical engineering to satisfy the exploding demand for graduates with specialized knowledge in and experience with fuels, lubricants, dyes, textiles, metallurgy, fertilizers, and other industrial lines.

This evolution happened quite continually. In the 1920s, the mechanical engineering department strengthened its automotive and engine-related programs, civil engineering introduced coursework in aerial mapping, biology would develop a sub-track called industrial biology that had a heavy focus on food technology, EE shifted resources towards communications such as radio and telephones, a major in building construction was added—and the list goes on.

Why Tech rejected proposed Harvard mergers

I’d be remiss if I didn’t say something in this article about Harvard’s constant efforts to merge with MIT in the early years of the Institute, since it says a lot about Tech’s culture. These mergers were something that the most ardent supporters of Tech’s mission among Tech alumni, students, and faculty felt very strongly about. And that strong feeling was often, ‘Absolutely not!’ Tech Presidents were always expected to hear out these merger offers, as Tech was quite poor and always in need of funds and space which Harvard did have. And the Presidents were on one or two occasions quite enthusiastic about the idea because they understood all too well just how dire MIT’s financial situation was. But the ardent students, alumni, and faculty were never so enthused. They did not trust Harvard. And culturally, it was just different.

Pritchett, while by many accounts a great President, was eventually run out of office. His cardinal sin: seeming a little too open to Harvard’s courting of a merger. Also, many did not like his propensity to compare how Tech did things with how Harvard or Yale did things. His attempts to tinker with Tech terminology, such as referring to workshops as laboratories, were not viewed as in line with Tech culture. Students were proud of workshops as places where they went to learn the parts of their future professions that required getting their hands dirty. A place, as Alexander referred to it, “where for decades students had proudly carried out grubby functions in grubby settings.” One student mockingly wrote in 1902:

A fellow used to walk through the mud of the alley into the shops, then jump into his overalls, and start to work like a man. Now he must promenade through the avenue into the ‘laboratories,’ clothe himself in a protective raiment, and practice the mechanic arts. — A Widening Sphere

Tech men were proud of what Tech was. They’d chosen this. They were starting to feel they had a President who would rather be something else.

They understood why Harvard wanted them. Harvard, a place that prided itself on its excellence, had a school of applied science and engineering just across town that was likely better than they were. Why not try to merge forces?

And the Tech men were likely right to have their concerns. The schools had very different approaches on how faculty should be spending their time, for one. At one point, the schools ran a (brief) joint experiment by allowing students in certain majors to obtain a joint degree from the two schools. Alexander wrote:

Lowell [the Harvard President] insisted that leaves be granted for recreation, study, or book writing only, while Maclaurin [the MIT President] argued that Tech’s policy—allowing a faculty member to consult for industry, teach somewhere else, work in a laboratory overseas, conduct experiments, get involved in whatever would keep him abreast of developments in his field—made more sense from the engineering educator’s perspective.

The schools also had very different ideas about how to manage students. Lowell fussed about the dangers of sending students out to do field work as he was concerned about the safety of his students. Maclaurin retorted that all would be well, “provided our men do not play the fool.”

If the schools would have merged, it is very likely that the MIT side’s fears of ending up as a richer Institute with more floor space, but with traditional academic masters who did not grasp the culture of their school would be realized. MIT served its mission above all else. When the decision came up in 1927 on whether or not MIT should allow students to have a Flying Club, despite the obvious dangers of students flying dangerous aircraft, the Institute allowed it. President Stratton wrote:

Aviation is growing by leaps and bounds; fatal accidents do not check its progress in the slightest degree, any more than the enormous loss of life on account of automobiles has checked the growth of that industry.

This is just how MIT was.

The need for a new, early-era MIT

It seems clear, given MIT’s transition to a more university style of education, that we are left with a hole. We do not have an elite hybrid technical school/applied research institute like this that can draw top talent away from places like Harvard and Stanford to its more hands-on style of education. But, as a country where the manufacturing sector is shrinking (and median wages aren’t doing so well either), we may need a new MIT now more than ever.

There are plenty of individuals at top schools who COULD be swayed to attend a place like this. Speaking for Stanford, where I went to undergrad, there was a large population of people who majored in mechanical engineering and were disenchanted because they did almost exclusively problem set work and very little building of anything real. And I knew even more people majoring in other subjects who abandoned mechanical engineering and majors like it for this reason! “We’re training you to be mechanical engineering managers, not traditional mechanical engineers,” was a common line used in the department. And, while that is a fine goal for a program, it is not what many of the students seem to want. What if I just want to be a top-flight regular engineer who can build awesome stuff?

An institute that trains and applies top minds to truly technical work could be an invaluable way to reallocate this underutilized talent pool. Dan Wang’s fantastic piece, How Technology Grows, outlines just how hard it is to innovate when you are not involved with the production process.

Both the design process and production process generate useful information, and dislocation makes it difficult for that information to circulate. I think we tend to discount how much knowledge we can gain in the course of production, as well as how it should feed back into the design process…

…I think that the weakness of the US industrial robotics sector is instructive. The US has little position in making high-end precision manufacturing equipment. When it comes to factory automation systems, machine tools, robot arms, and other types of production machinery, the most advanced suppliers are in Japan, Germany, and Switzerland. I think the reason that the US has little position can be tied directly to the departure of firms from so many segments of manufacturing. How do engineers work on the design of automation systems if they don’t have exposure to industrial processes?

A quote from the article: “A report to President Barack Obama on advanced manufacturing, prepared by his council of science advisers in 2012, concluded that the ‘hard truth’ was that the U.S. lagged other rich nations on manufacturing innovation.”

I don’t see enough Americans being troubled by the idea that America isn’t making advanced industrial robots. It might be fine to think that robots will be doing all the manufacturing work in the future; but someone has to build these robots, and own the IP of advanced robot making, and for the most part, that someone is not the US. It can’t be an accident that the countries with the healthiest communities of engineering practice are also in the lead in designing tools for the sector. They’re able to embed knowledge into new tools, because they continue to generate process knowledge.

Wang’s point is made even stronger given how weak the US is in this area despite its massive allocation of capital to academic AI research. The work that Wang describes is exactly the kind of work that early-era MIT trained students to do at a high level. (I will talk more about how MIT’s transition to its current form happened in the third piece in this series.)

Major universities will most likely not be willing to entirely revamp their curriculum, faculty, and equipment to implement an early-era MIT-type environment. Even if they wanted to, there are likely too many internal entrenched interests and too much administrative inertia to make such a transition workable. But, I see little reason that one of two things could not be possible:

- A large, possibly-elite university can start an adjacent institute dedicated to the principles of early-era MIT

- A high-net-worth individual who has some cultural sway with young people, a Peter Thiel type, can either start their own modern-era MIT from scratch or buy out an existing trade school and attempts to turn it into one.

MIT was once a startup, experimental school with meager resources and few students. In the beginning, an incoming class at MIT was only about 15 people and offered only five majors. And it did some of its most impressive educational work in these early decades! There’s no reason a modern-day William Barton Rogers could not do this again. Building a place for these hyper-intelligent true builders to let their skills and curiosity for physical things shine could prove remarkably productive for US industrial progress.

An enterprising individual or university could identify which areas of manufacturing the US has managed to keep intact and which areas are likely to grow in the coming decade. Then, they could identify a handful of majors in which a hands-on technical education + training in the right scientific principles could optimally serve that industry. Top that off with about ten or so of the right instructors, possibly many of them part-time, to cover hands-on education as well as the science, and you have yourselves the makings of a 21st century analog of the experimental school that was MIT in the 1860s.

It wouldn’t be trivial, but in a world where everyone seems to be vexed by what do to about our manufacturing problem and difficulty innovating in large-scale industry, trying what seemed to work the last time doesn’t seem like such a bad idea. Setting up a new MIT could prove to be a shockingly fruitful experiment for what it costs.

And, at least to me, it sounds pretty fun.

END NOTE:

If any of you are interesting in further discussing how to make this happen in detail and what this setup process could look like, please just DM me on Twitter and I’d be happy to discuss.

In the next piece (which will be released a day or two after this piece), I’ll be discussing how research projects at the Institute worked differently in the early decades and what made them remarkably effective.

P.S. I have freed up some time in my schedule and am looking to take on more progress studies-related work. If you’d be interested in partnering on anything, please reach out! I’m fascinated by everything related to the space and love doing applied work as well as things like writing.

[…] first piece in this series covered the early decades of MIT and its approach toward educating many of the engineers who would […]